Air Purification System for 3D Printers (FDM and Resin)

3D Printing Fumes and Particles

As many within the 3D Printing community know, ABS, nylon, and other Fused Deposition Modeling (FDM) materials used in 3D printing emanate toxic fumes and particles. Resin 3D printing (SLA and DLP) are also known to be toxic and produce fumes. These two toxins are broken into two categories: Particulates from FDM and volatile organic compounds (VOCs) created by FDM and Resin printing. Both of these are emitted at high concentrations, and can have harmful effects to humans. The particulates are actual small pieces of plastic circulating in the air that are essentially invisible, ranging from 10 microns to the size of nanoparticles! These particulates are typically cleaned using simple filters. VOCs, however, are toxic gases that cannot be filtered out like particles, they need to be absorbed (adsorbed, technically - but more on that later). That is why makergadgets developed the 2 Phase Air Purification system used in all of our Professor Enclosures. Read on to learn about how the system works and see the results of our purification lab tests from our whitepaper.

NOTE: Interested in learning more about the danger associated with 3D Printing Fumes? Read our article - Are 3D Printer Fumes Dangerous?

2 Phase Air Purification System

Makergadgets' 2 Phase Air Purification uses (as implied) 2 filter mechanisms. As you can see in the image above, the first step in the filtration is the outer HEPA filter. The HEPA filter's purpose is to remove the particulate concentrations in the air. The next phase of filtration is a thick layered Activated Carbon Filter, which is used to adsorb (not a typo!) toxic VOCs. The system works in our enclosures because of the recirculation environment created. Essentially the filter pumps air within the enclosure and continues to recirculate the toxic air until all particulates and VOCs are removed or brought to a safe level. Let's dive deeper into the mechanisms of the 2 Phase Air Purification System!

HEPA Filtration - Fine and Ultrafine Particle Filtration

HEPA Filters, or High Efficiency Particulate Air Filters, are essentially fibrous netting meant to capture particulates in the air. There's a common myth that HEPA filters cannot filter out ultrafine particles (or nanoparticles), sometimes pushed by fancy air purifying consumer products. However, that's far from the truth! While HEPA are often claimed to be rated for 0.3 micron sized particles, they are actually capable of filtering out nanoparticles at higher efficiencies. This misconception is due to our simplified understanding of how HEPA filters work. As illustrated in the example image, we expect this larger micron sized particle to get stuck in the HEPA fibers since it's larger than the netting.

However, nanoparticles do not move in traditional straight pathways as we would expect. When particles are that small, they move in what's called Brownian motion - meaning they move chaotically in zig zags through the air. As you can see in the example, this causes the nanoparticles to be more likely to get caught in HEPA filters (hence the higher efficiencies). Don't take our word for it! NASA has found that "HEPA-rated media provides superior performance for removing virtually 100% of particulates." Furthermore, a study by the University of Minnesota using silver particles ranging from 3 to 20 nanometers, found that HEPA filters capture 99.99% of particles smaller than 5 nanometers, and that the filtration improved as the particles grew smaller.

Activated Carbon - Adsorption of Toxic VOCs

Activated Carbon is essentially charcoal treated with chemicals to create micropores that increase its overall surface area. One gram of activated carbon could have greater than 3,000 square meters of surface area! The increased surface area improves its ability to adsorb VOCs. As we mentioned earlier, Activated Carbon adsorbs VOCs, not absorbs. For simplicity, we use the term "absorption" in our images, but the difference lies in the mechanism. Absorption, scientifically speaking, means that the absorbing entity is actually enveloping the substance. Imagine a paper towel soaking up water; the water is going into the paper towel itself. Adsorption, on the other hand, means that the adsorber is having the substance bind to its surface through a chemical reaction. Imagine, if you can, molecules in the air passing over a glue trap and getting stuck to the surface of the trap. So activated carbon, with it's porous large surface area, actually has these toxic VOCs bind to the surface of the carbon as the air flows through. In order to ensure adequate cleansing of VOCs in our 3 Phase Air Purification system, we use two loose-filled activated carbon filters for two passes at adsorbing VOCs.

Recirculation System

The last core component of our Air Purification system is the recirculation system created by enclosures like our Professor Enclosure. The 2 Phase Air Purification system is designed to be turned on during print jobs. The system pumps air through the outer HEPA filter, and pumps the more purified air out through the two Activated Carbon filters. The filter is recirculating previous cleansed air over and over again. Eventually the system clears all contaminants.

So now you understand how our 2 Phase Air Purification works! However, you may be still wondering how we know it's actually purifying the air sufficiently enough to keep you safe. That's completely understandable. At makergadgets we want you to Print and Breathe Easy. So that's why we've performed rigorous tests on our system. We'll focus on these tests next.

Testing the Cleansing Performance of the 2 Phase Air Purification System

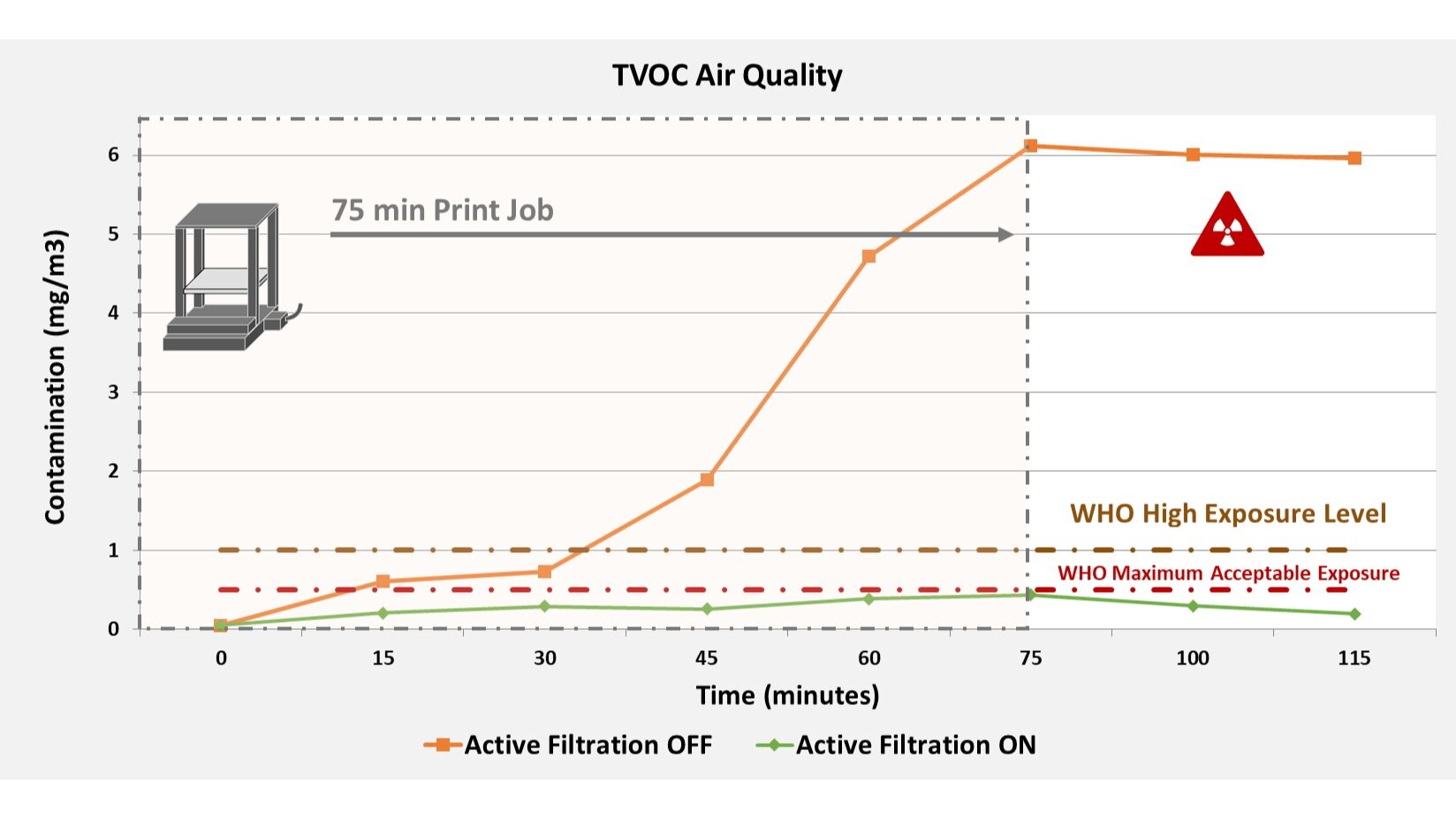

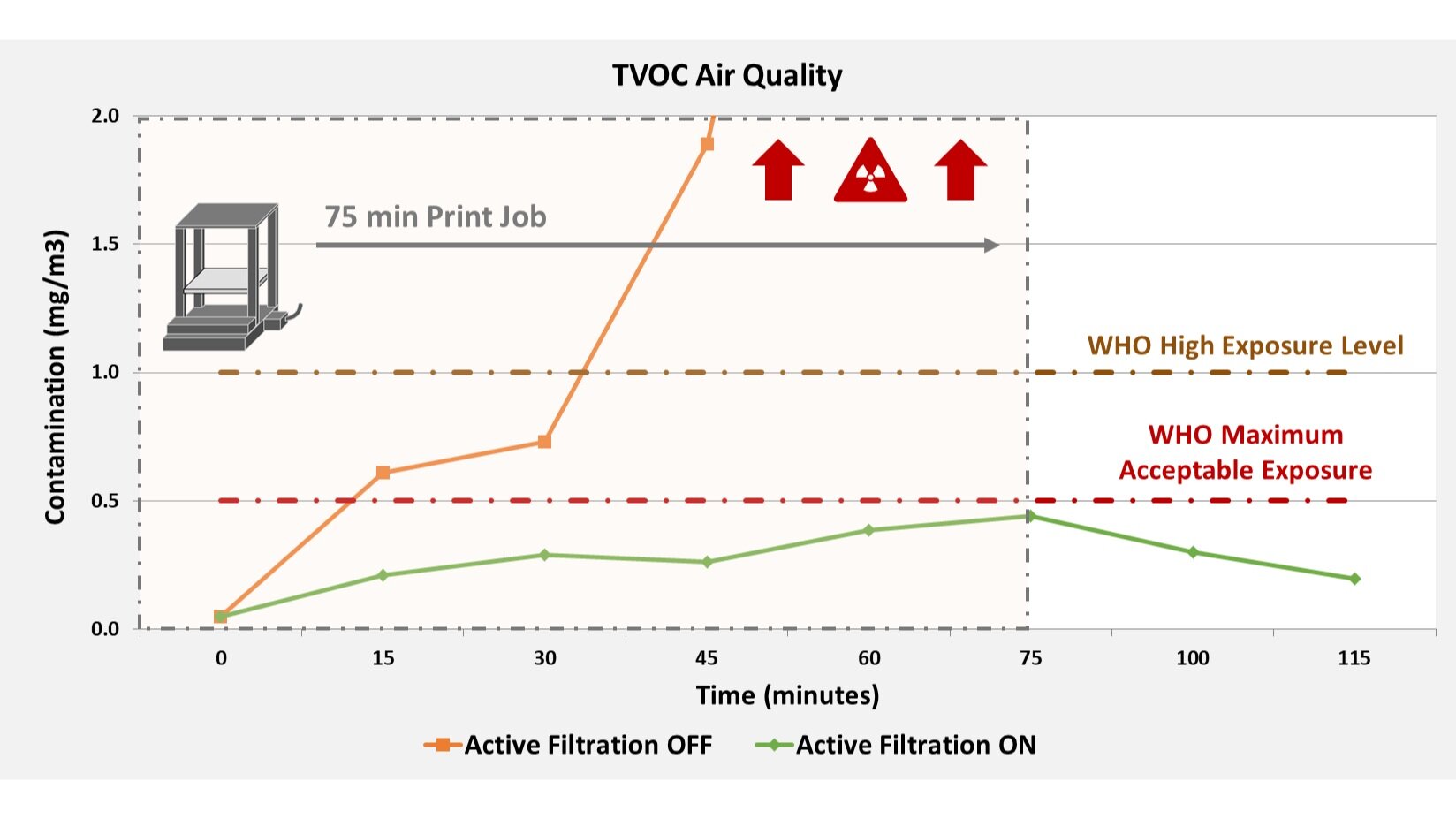

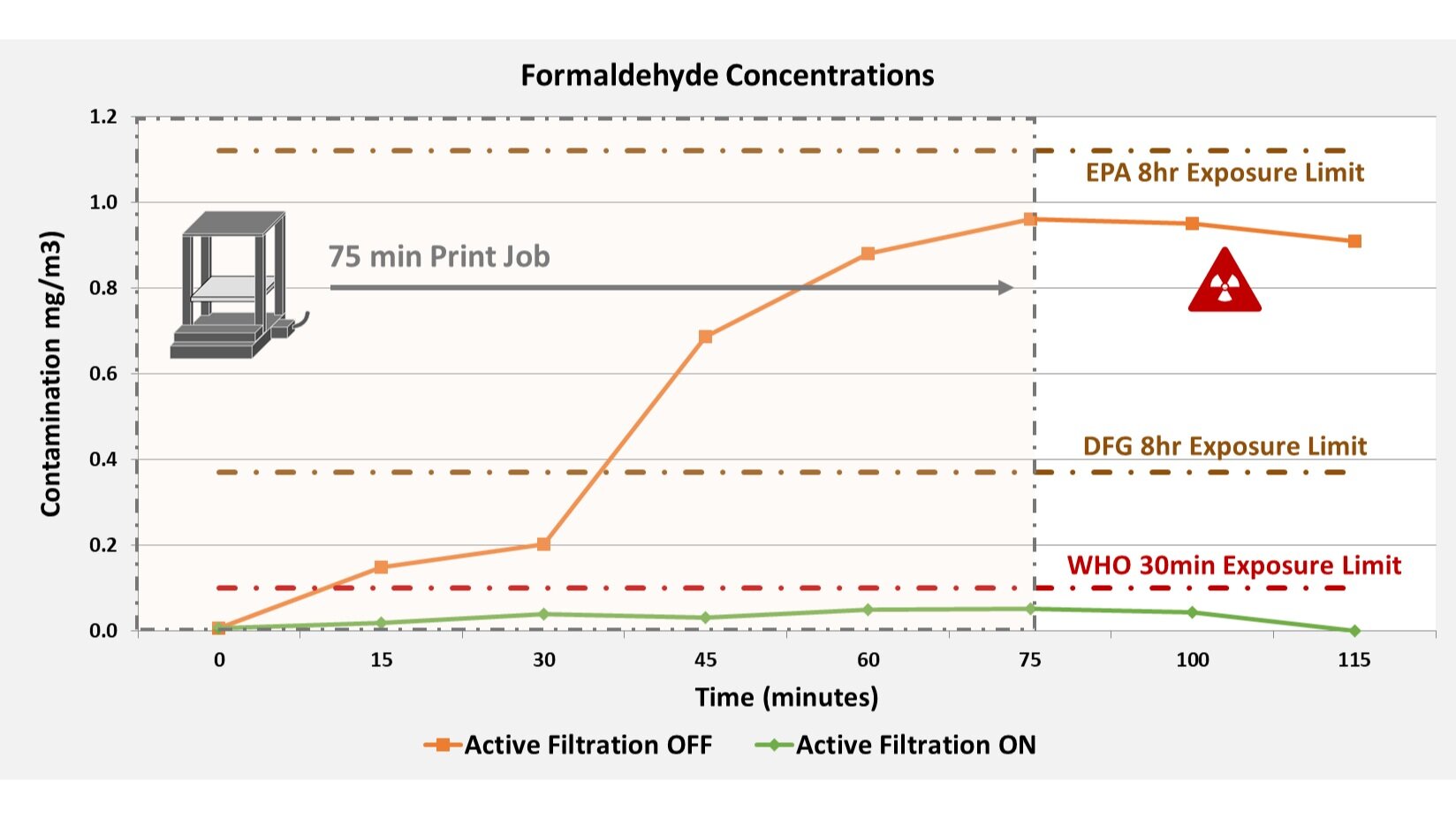

At makergadgets, we set out to prove that our 2 Phase Air Purification system can cleanse contaminated air caused by 3D Printing. First, we needed to understand what concentration levels of particulates and VOCs were actually harmful to humans. We leveraged the standards from WHO, the EPA, ACGIH, NIOSH, and DFG to obtain maximum exposure limits for each of the contaminants found in 3D Printing.

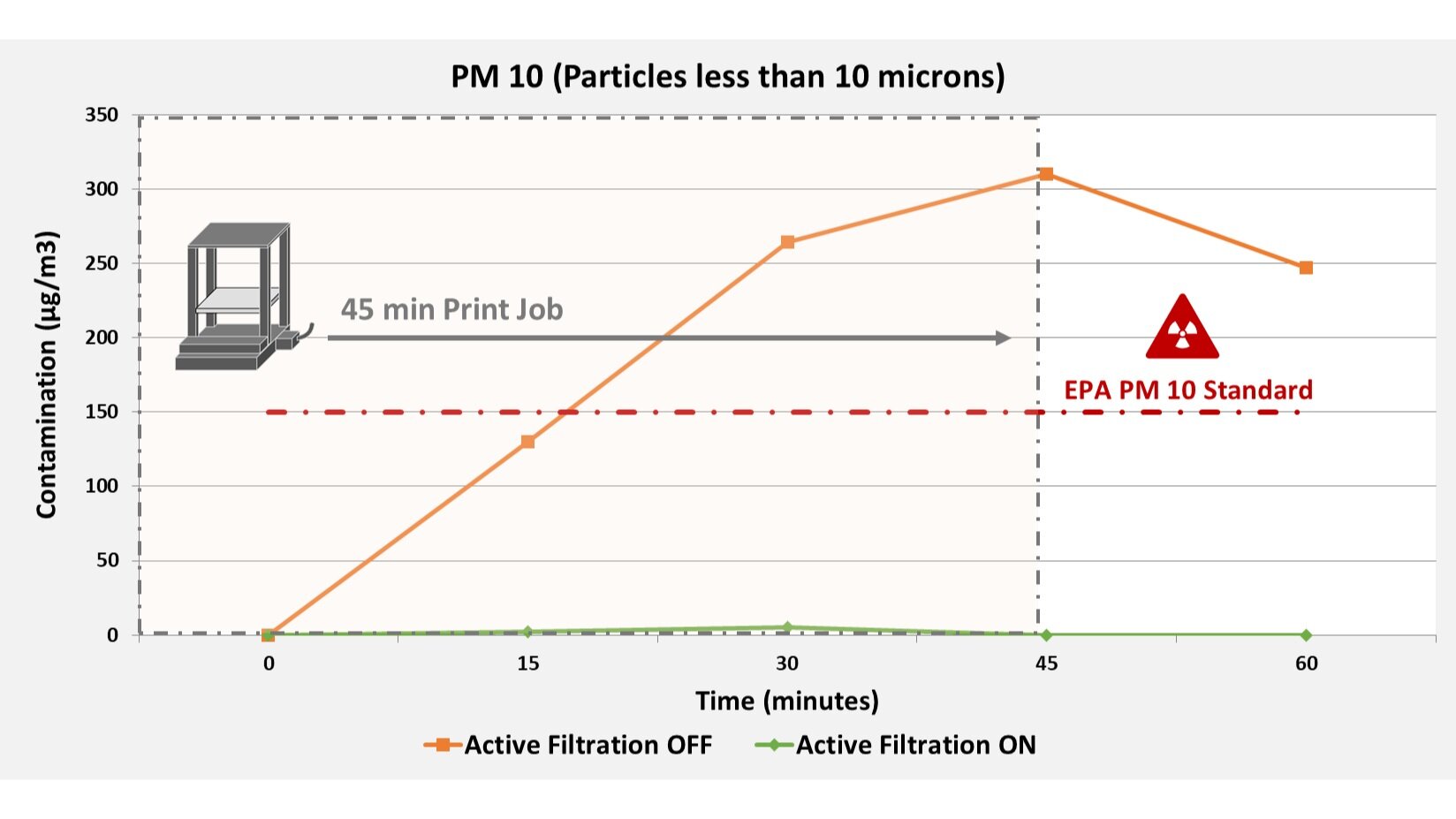

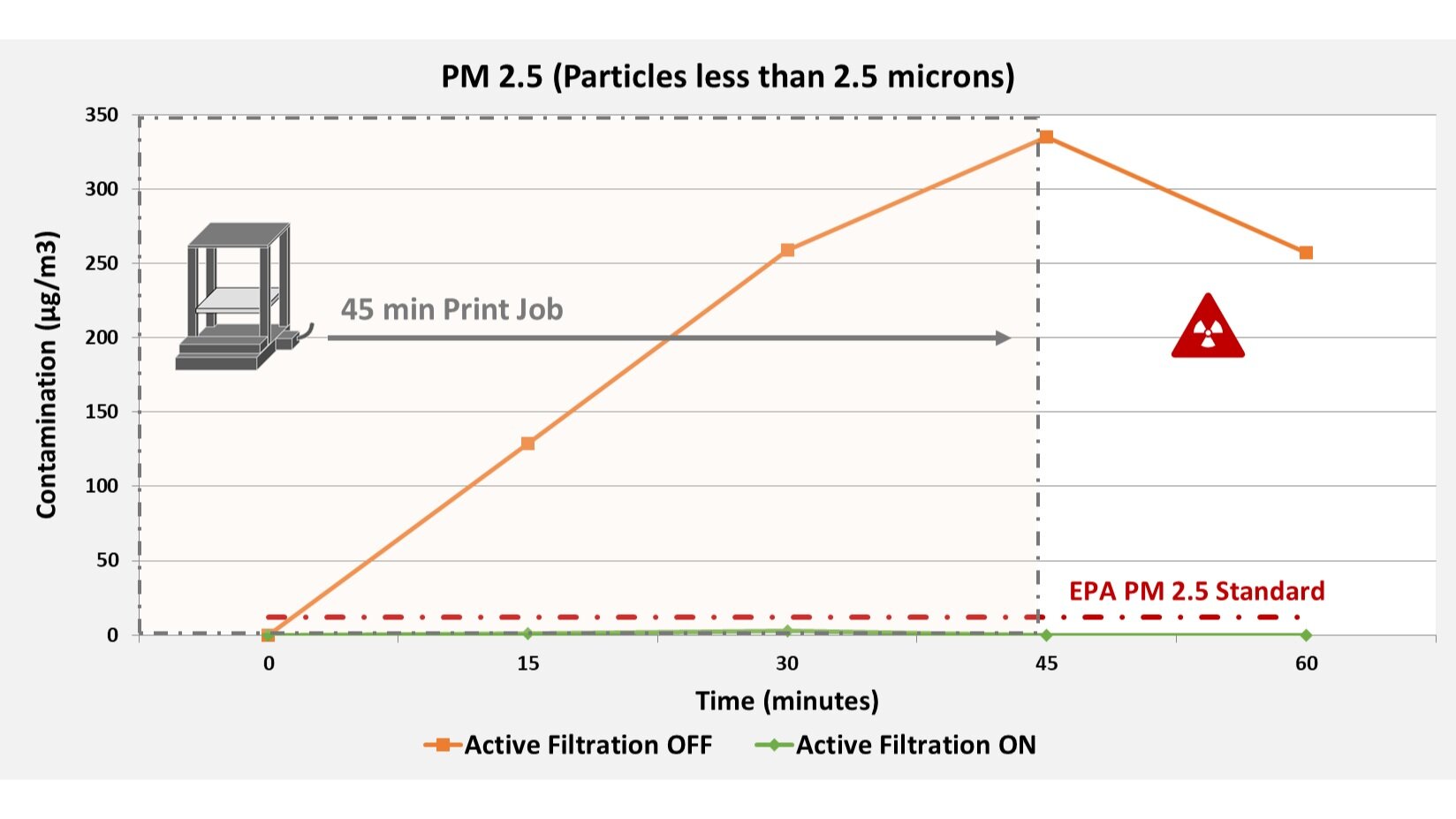

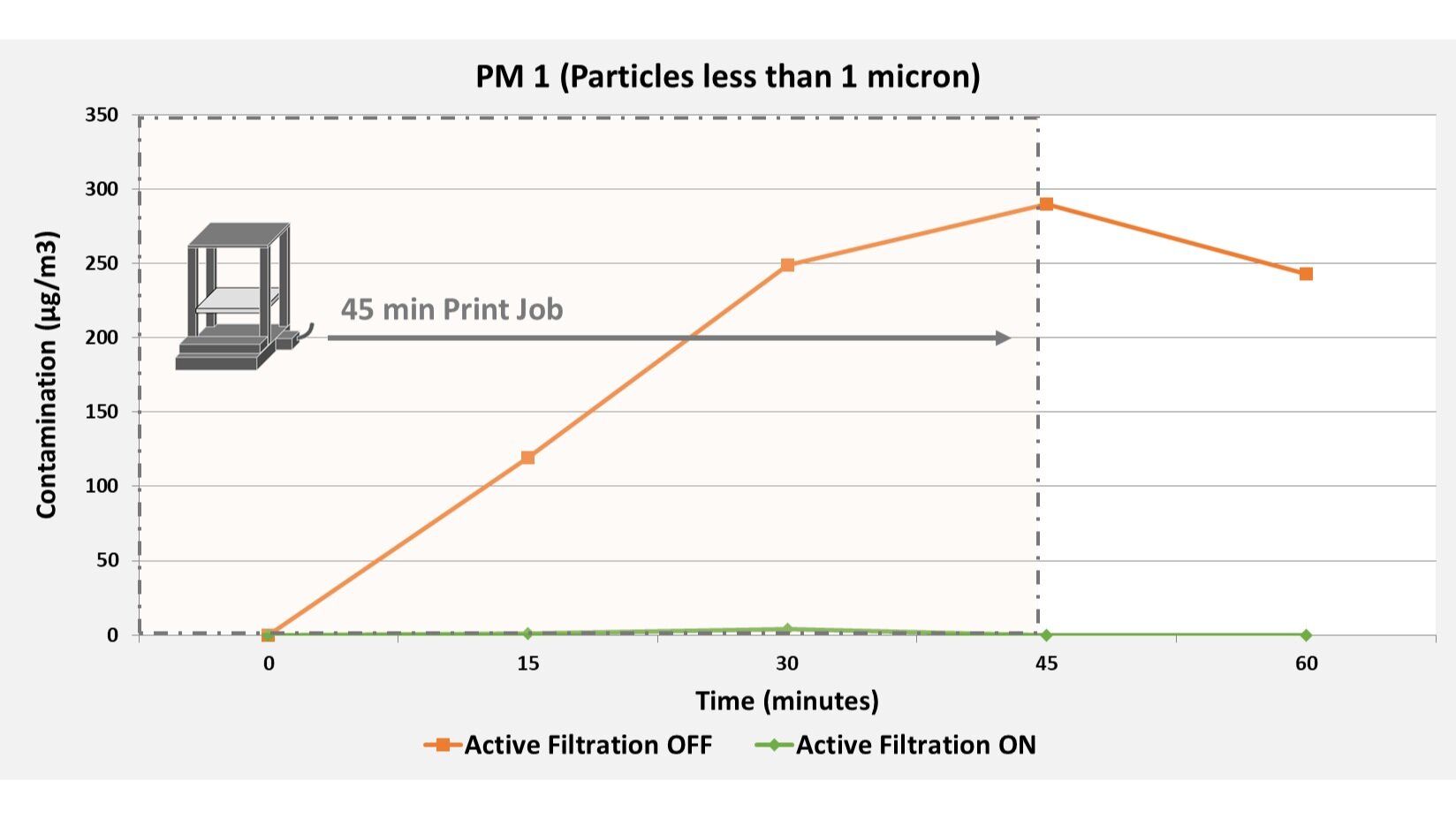

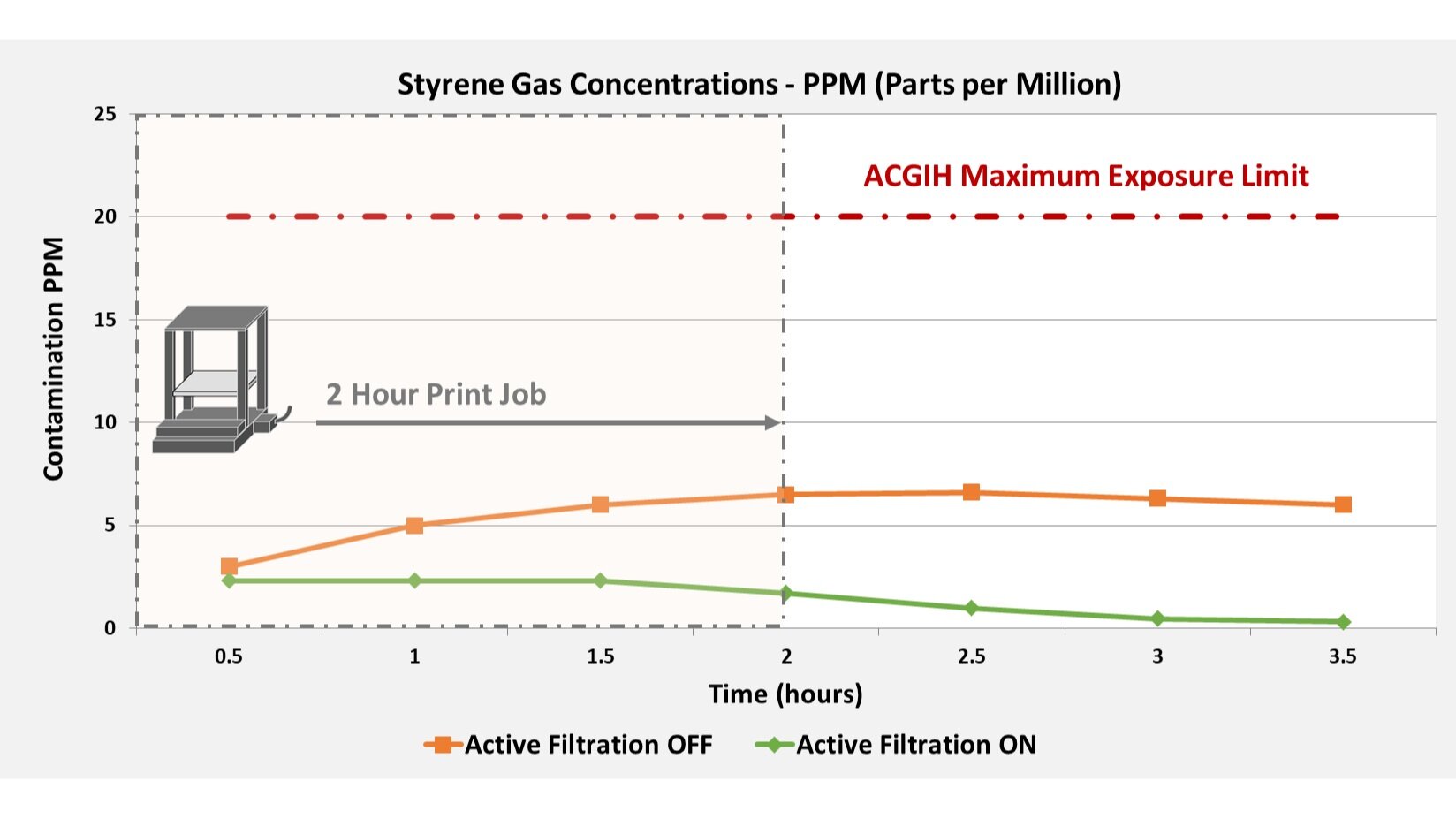

With this information, we set out to test our Professor Enclosure in a variety of settings with the 2 Phase Air Purification system turned on during the print jobs (noted as "Active Filtration ON"), and with the system turned off (noted as "Active Filtration OFF"). We tested for total VOC concentration (TVOCs), as well as the specific VOCs of concern: Styrene and Formaldehyde. We also tested for concentrations of particulates less than 10 microns, less than 2.5, and less than 1 microns in size.

The results were impressive. We found that printing without the 3 Phase Air Purification system resulted in toxic levels of TVOCs, Formaldehyde, and Particulates (note that Styrene concentrations stayed within ACGIH Maximum Exposure Limits). Most alarming was how high the TVOC levels were. Without the system turned on, TVOC levels were nearly 12 times greater than the WHO Maximum Acceptable Exposure Levels!

More importantly, when the 2 Phase Air Purification system was ON, all concentrations of VOCs and Particulates were vastly lower, and well within the maximum exposure limits recommended by the agencies. You can see the results in the images provided below, dictating the length of the print jobs and the concentration of the toxins over time.

As you can see, the 2 Phase Air Purification system and the Professor Enclosure ensures that toxic fumes caused by 3D Printing are efficiently cleansed to safe levels. You can learn more about our test by reading our whitepaper Assessment of 2 Phase Air Purification System. If you have any additional questions, do not hesitate to reach out to us at [email protected].

We thank you for learning more about our technology and we hope let's you Print and Breathe Easy!